Pilot Experiments

3D Printed Heat-Exchangers for Household Coffee-Machines

Lombardy and Piedmont, Italy

![]() Kilometro Rosso

Kilometro Rosso

Experiment objective

3D Coffee’s aims at designing and validating the performance of a non-electric thermal management system enabling a more efficient and sustainable coffee preparation. In detail, it aims at finding the optimal topology of a conformal, high-efficiency, passive heat-exchanger and test its performance for applications in household coffee machines.

Challenges

The heat-exchanger needs to fit in a compact volume and guarantee effective cooling capabilities to comply with the application’s standard pressure/temperature values, as defined by literature. In particular, it needs to provide a maximum temperature drop in the range of 90°C to 120°C while minimizing the pressure drop (maximum pressure should stabilize in a range between 7 bar to 9 bar).

Due to the porosity nature of coffee, which largely depends on the particles size and their distribution (typically binomial) and on how the ground is distributed inside the filter during preparation, the variability factors shift across a wide range of possibilities. That makes the challenge even greater, and despite the fact that the experiment time-frame will not allow for a full investigation, our multidisciplinary approach will help to pave the way (i.e., the framework) for future research.

That is also why the experiment will leverage the capabilities of advanced Topology Optimization software tools combined with Computational Fluid Dynamics and metal 3D printing. This interdisciplinary approach makes it possible to design and test optimal complex geometries in a relatively short amount of time. Consequently, driven by an agile manufacturing approach, the team will perform multiple small/rapid iterations to reach the expected results within the six-month timeframe. On top of rapid prototyping, the use of 3D printing technology throughout the experiment will allow performing an in-depth assessment of the technology (specifically Direct Metal Laser Sintering) as a production process.

Implementation Solution

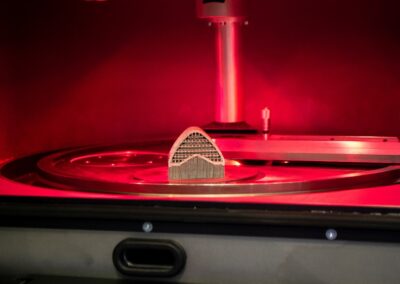

This experiment will advance the digitalization level of Additive Appliances (AA) and will overall shorten the company’s innovative products’ time-to-market. 3D printing and MBD will improve AA’s prototyping and production processes, shorten the product development life cycle, and boost the company’s competitiveness. Furthermore, since digital production is among the key drivers of the AA’s business model, the collaboration with Kilometro Rosso will open up a broader set of opportunities, including technology scouting, best practices implementation, and networking. From a technological standpoint, the experiment will allow AA to advance its MBD approach by designing and testing the performance of the heat-exchanger prototypes in actual operational conditions and material thanks to Kilometro Rosso’s equipment -an EOS M290 printer working with Aluminum powders and performing automated quality checks. Furthermore, 3D printing specialists will support AA during the product design and optimization phases minimizing defects in the prototyping phase. Finally, AA will have the opportunity to co-work in the 3D printing laboratory, follow the entire prototyping process, assess the printing process, and improve its design accordingly.

Results Obtained

The main results obtained can be summarized as follows

- Advancement in the Model-based Design approach techniques

- Improvement and validation of the Digital Twin of the Heat Exchanger

- Feasibility (i.e. temperature and pressure control) in extreme boundaries conditions

- Cost assessment of 3D printed core-components

- Applicability of the Heat-Exchanger solution in various coffee-machines configurations

Technically, the experiment proved possible the cooling of hot pressurized water in a very challenging shape-configuration, where tight boundary conditions apply. Since we chose the most challenging configuration among all coffee brewing devices, namely a small thermo-mechanic equipment such as the moka pot, we can indeed state that the potential of this application is wide and solid.

Impact of the experiment

The application has the potential to substitute a bunch of hardly recyclable components (those embedded in electro-thermic coffee maker to control temperature and pressure) with a single component made out of aluminium or stainless steel -therefore easily and fully recyclable.

The fall out is both economical (seen from a circular economy perspective) and environmental -thus with an indirect societal impact. Moreover, the “coffee ritual” brings together people from around the world, being the second most consumed beverage worldwide. Since our solution values specialty coffee producers, it has a secondary yet not negligible impact over responsible farming -and not only consumptions.

Dissemination

- https://dihworld.eu/event/fostering-digital-twin-transition-with-dih-world-eu-network-in-lombardy-rainbot-and-3d-coffee-projects/

- https://www.kilometrorosso.com/en/services/projects/3d-printed-heat-exchangers-for-household-coffee-machines-3d-coffee/

- https://www.kilometrorosso.com/wp-content/uploads/2021/11/Brochure-3d-coffee-A5_def.pdf

- https://www.metal-am.com/additive-appliances-looks-to-am-for-coffee-machine-heat-exchangers/

- https://www.3dnatives.com/it/additive-appliances-270120229/#

- https://3dprintingindustry.com/news/coffee-machine-burnt-out-additive-appliances-could-have-you-covered-201014/

- https://www.3d-grenzenlos.de/magazin/3d-objekte/3d-druck-waermetauscher-haushaltskaffeemaschinen-27795303/

- https://www.3dprintingmedia.network/3d-coffee-the-next-coffee-revolution-enabled-by-3d-printing/

- https://www.ecodibergamo.it/eventi/eppen/dettaglio/incontri/bergamo/additive-manufacturing-soluzioni-e-applicazioni-per-la-sostenibilita_161585/

- https://www.replicatore.it/3d-coffee-la-prossima-rivoluzione-del-caffe-abilitata-dalla-stampa-3d/