Pilot Experiments

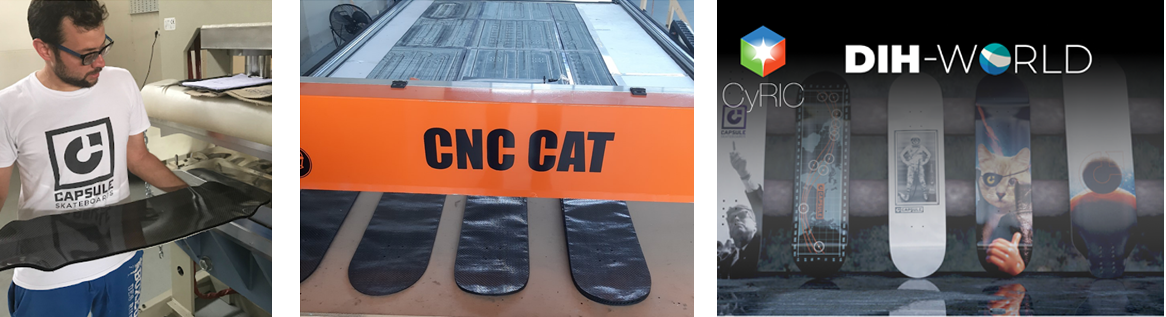

Capsule Skateboards: Robotized laser cutting and automated fabric layer stacking system for self-reinforced polymer composite fabrics

Experiment objective

The experiment is related to the production process of Capsule skateboards using a unique polymer composite material and the integration of robotic systems in the production line. The material is available in the form of fabric rolls. Capsule is currently manufacturing three different types of skateboard decks (Shortboards, Cruisers and Downhill) in terms of their usage. Every skateboard deck has a specific shape and number of fabric layers. According to the type of deck that it will be manufactured, the fabric has to be cut and stack. Then the fabric stack proceeds to the thermoforming process to create the desired shape.

To optimize the production of the revolutionary skateboard deck it is essential to integrate robotic systems to every possible stage of the production line, since the various processes until today is done manually by workers. This is expected to improve productivity, impact product consistency and quality, and result to material and energy savings

Challenges

Challenge 1: Calibration between hardware and software while keeping the production process in place in order to achieve smooth transition without stopping the production facility

Challenge 2: Covid-19 had some delays on the delivery

Implementation Solution

The solutions is a robotized laser cutting and automated fabric layer stacking system for self-reinforced polymer composite fabrics. The novel technology introduced in this project evolves development, integration and optimisation of different robotic systems for efficient utilisation of composite material layers, aiming to offer a solution with potentials of wide applicability in the sector of multilayer composite materials

Two robotic platforms have been introduced dedicated to specific tasks:

- Precise shape cutting of fabric using a 3 axis cartesian robotic laser cutter.

- Precise collection of shaped fabric from a 4 axis cartesian Pick’ n Place robotic manipulator.

Results Obtained

Through the experiment we managed to achieve a huge a milestone for the company. The digital transformation we have achieved has enabled us to

- Improve the efficiency and production time of the raw material into skateboard shapes from 60 minutes down to 20 minutes. This means that we have at least tripled the production capacity of the company.

- Improve the quality of the final product because of the laser cutting utilization into the production. Prior to the DIH world experimentation the above process was performed manually and with hand tools. The quality of the cutting edges due to the laser integration has provided the skateboards with a beautiful and elegant result on the product that satisfies the end users.

Impact of the experiment

The overall experiment has been significant for the company itself but also with a direct impact and benefit to its customers as well

Indicatively, the benefits can be considered beyond expectation because

- The digital transformation of the production line has improved our production capacity from 60 minutes per board down to 20 minutes maximum

- The digital transformation of the production line has improved our final quality product since the laser cutter perform precision and high-quality cuts of the material – better product quality for the end user – less time for us in quality assurance control

- The digital transformation of the production line has injected significant automation in our production line which expands our companies’ abilities further since we can idealise new concepts much faster – hence creating new products and bi-products and reach a larger customer audience.

- The digital transformation of the production line has enabled us to introduce new concepts for the consumers as well as new structures for lighter and stronger products

Additionally, the ability now to produce faster and with better quality is significantly helpful during our negotiations with retailers in the B2B market since we are more confident to guarantee larger baches of product shipments with higher margins both for us but also for the B2B retailers.