Experiments

DigiCompost: Digitalising organic compost manufacturing

Greece, Peloponnese Region

![]() Green Supply Chain DIH

Green Supply Chain DIH

Experiment objective

Organic compost is a nutrient-dense, cost-efficient natural fertiliser which supports soil regeneration and the increase of soil organic matter. In Greece and many other countries in the region, due to cost limitations and/or lack of digital skills, the manufacturing of compost, which is taking place in open space piles, is mainly manual. This includes both the monitoring of the compost conditions, which is limited to manual daily checks of the pile’s temperature, but also the decision making and management process, including compost irrigation and stirring activities. The main objective of DigiCompost project is to help Agroecology Lab in digitalising its organic compost production, enabling the digital transformation of the company, while supporting the sustainable transition of the agricultural sector as a whole.

Challenges

Based on the new EU legislation on fertilisers applicable as of 16/6/2022 and in combination with EU Fertilising Products Regulation there is a need for improving and making more precise the applied compost manufacturing process especially when the compost is onwards considered and regulated as “organic fertiliser”. To date the majority of the companies, especially in Greece, that produce organic compost do not use a standardised process – neither are able to “predict” the “Nitrogen Phosphorus Potassium” (NPK) content of the produced fertiliser, something that is required from the forthcoming legislation. To this end, DigiCompost is focused on co-designing, deploying and testing a solution that will digitise the overall production process, offering extensive supervision, control and optimisation over it along with prediction capabilities on the compost’s nutrients and time of completion.

Implementation of the Solution

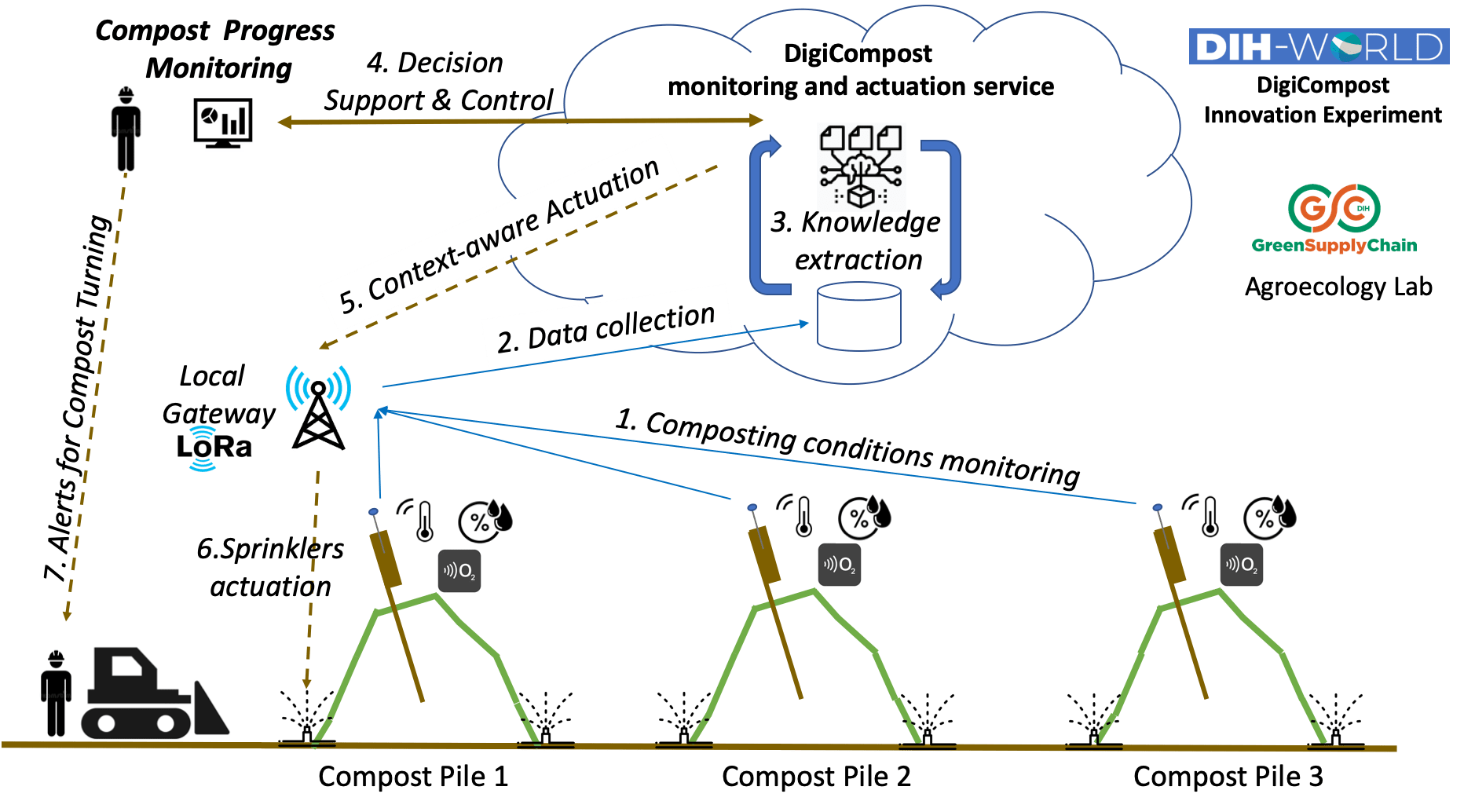

The innovation experiment is focused on co-designing, deploying and testing a solution that will digitise the overall production process, offering extensive supervision, control and optimisation over it along with prediction capabilities on the compost’s nutrients and time of completion. Selected (I4MS) technologies will be integrated into DigiCompost solution: Sensors monitoring the compost pile’s conditions (Temperature, Moisture, pH, O2), IoT technologies for data collection and persistence (wrapped around LoRaWAN), Data analytics (including Machine Learning and AI that will allow to identify correlations among monitored parameters and compost process/outcomes) and Smart Modeling that will support the decision making for automated actuation (compost sprinkler activation when temperature and humidity are above/below a threshold) or dynamic notifications for actions (e.g. usage of compost turner to aerate the compost). DigiCompost will focus on the concurrent management of multiple piles of large volumes of heterogeneous organic raw materials that are composted in open spaces. At the same time relevant restrictions that will be considered are to keep the environmental footprint, the financial investment cost and overall nuisance level to minimum. In order to monitor critical metrics in the field, i.e. parameters related to compost conditions, a technical infrastructure which incorporates and combines sensor devices for recording metrics, RF network for data transmission and a light IT infrastructure for data persistent storage and visualisation, will be utilised.

Dissemination

https://www.greensupplychain.eu/our-projects/ Green Supply Chain DIH website presenting the experiment