Experiments

KF SMART

Romania, Moldova (North-East Region), Iasi

![]() Digital Innovation Zone

Digital Innovation Zone

Experiment objective

Through KF SMART, we aim to create long-term impact (solving one of the industry’s most pressing challenges -reduce the pre-consumer waste of resources (fabrics, accessories, usable, utilities, logistics, carbon footprint, time) from the current overall 40% waste, in traditional design, cutting and sampling manufacturing, up to 5 % ) while increasing the digitalization level of Katty Fashion SRL [KF]. We will reach that goal by designing, implementing, and scaling at the regional fashion industry level a 6 months DIH-supported experiment around:

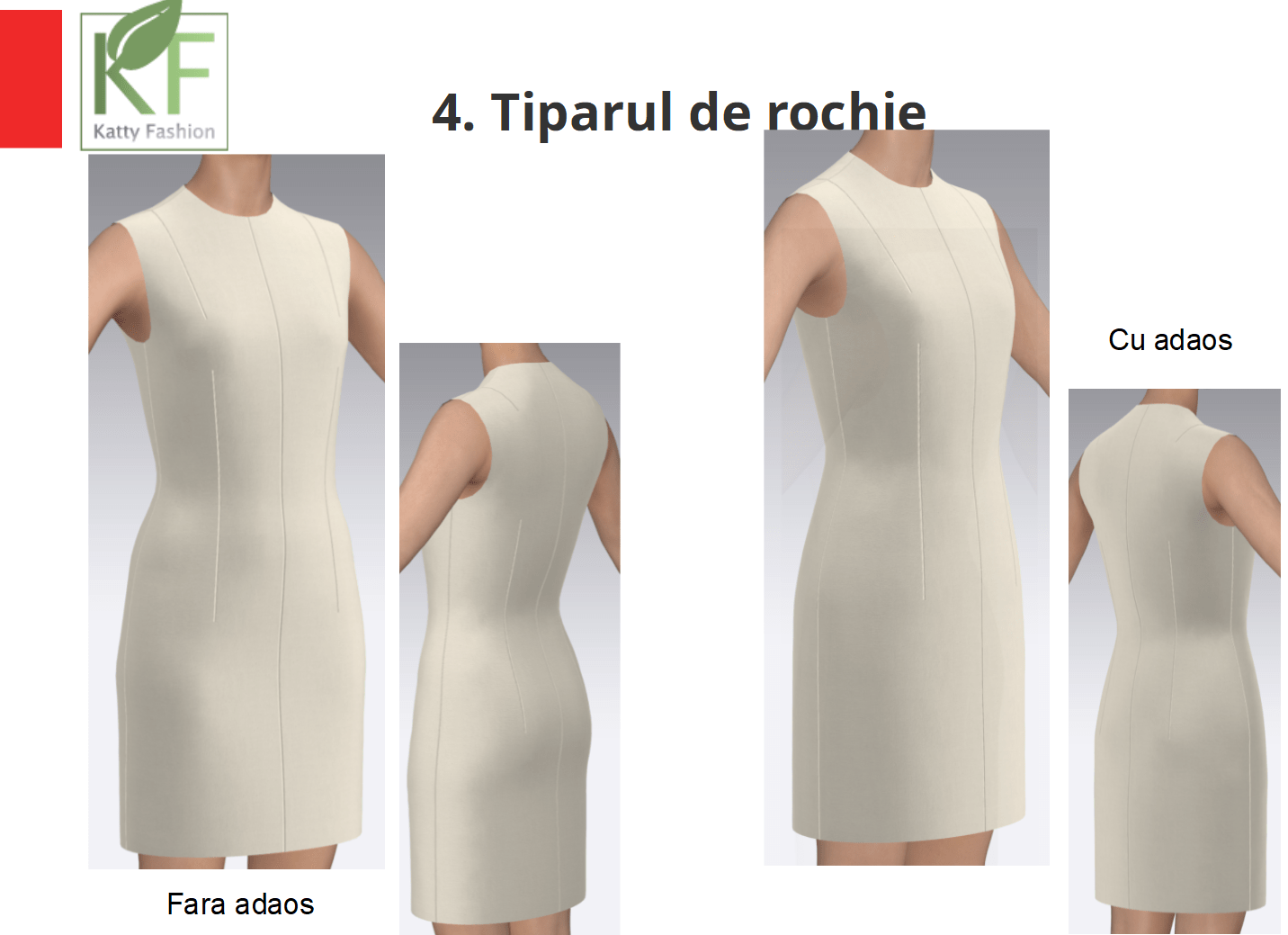

Objective 1: Development of a basic digital database of assets.(4 sets of tested, validated, customized, and reusable body shape avatars, pre-shaped pattern blocks virtual prototypes (VPs), fabrics type, styles feature, components, and accessories) linked with open costing sheets templates that will set the base for further market-adoption of KF smart-modelling future (collaborative design & virtual prototyping) service portfolio. It is an experimental step towards valid testing & integration of 3D design technologies into traditional design and product development in the regional and EU fashion industry. This will have the benefit of shorter, more effective production processes as typically physicall assets are turned into digital ones and replace the waste intensive, time consuming traditional production process. It will also allow collaborative designing with clients and thus faster order fulfillment. This will also improve company image as client experience is improved and Katty Fashion comes one step closer to fulfilling its commitment to sustainable green technologies

Objective 2: Solution validation.(a sustainable alternative to the traditional waste-creator design process – adopting the novel technology of collaborative design and virtual prototyping (VP) – smart modelling) with 4 KF’s relevant customers within 2 main product categories (home-wear and business chic women’s wear). If solution is validated, we aim it to become core KF service line in 2024. Solution validation will improve the quality of our developed solution and implicitly that of our products and capabilities. This will translate into better competitivity through quality, speed and sustainability related factors.

Objective 3: Developing a successful DIH business model around introducing Smart Modelling as an alternative to traditional wasteful design process in the fashion & textile industry in North East Romania region. This will boost competitiveness in the region and allow further development of digital skills in the north east romanian labour pool. With the Romanian textile sector being one of the biggest polluters and, at the same time, biggest employer, a business model shift, even if partially adopted, will have large environmental and societal effects.

Objective 4: Dissemination of DIH World consortium and network objectives under use-cases from the Romanian textile industry.Through experiment promotion we increase awareness of existent technologies, strategies and aforementioned difficulties in the textile manufacturing industry. This in turn may have a trickle effect and help companies adopt new technologies and become more competitive, sustainable and invest in digital skills.

Challenges

Challenge 1: The traditional design and product development communication & working flow, between fashion brands and manufacturers, require 1 to 2 physical toils/samples, prior to the start of styles collection development and 3 to 7 physical samples in product development and prior to going into production. Those intermediate samples are sent to customers for fitting sessions. Traditional product development implies an average of 2 fitting sessions that last 1-2 hours each to obtain the final prototype. These sessions translate for both fashion brands and manufacturers in added costs and shipping, increased consumption of materials, utilities, and all related pre-consumer waste.

Challenge 2: The majority of our clients are international businesses which adds strain on the communication channels and demands a higher resource investment from both sides in order to ensure product quality and accuracy. This can also be measured in the large amount of waste associated with the traditional manufacturing processes.

Challenge 3: Romania is consistently classified by the European Union as a country with low digitalization and low innovation levels, which leaves companies struggling with creating and maintaining a good competitiveness level, as well as a labour force remuneration on par with the western competitors.

Implementation Solution

KF SMART, proposed solution has 4 stages, with tasks , subtasks and targets , as follow:

Stage 1: Development of a basic digital database of assets (4 sets of tested, validated, customized, and reusable body shape avatars, pre-shaped pattern blocks virtual prototypes (VPs), fabrics type, styles feature, components, and accessories) linked with open costing sheets templates → that will set the base for further market-adoption of KF smart-modelling future (collaborative design & virtual prototyping) service portfolio. It is an experimental step towards valid testing & integration of 3D design technologies into a traditional design and product development service perfected in the last 2 decades and tested validated through this experiment,which also could be disseminated and replicated in the regional and EU fashion industry.In order to develop a strong digital asset database we will perform a series of activities:

- Analyze all KF Clients by:

- Extracting all relevant clients and developing a relevant client criteria table, under which the clients are sorted.

- Setting a weighted system for the criteria and implementing it in the table .

- Select the top 4 clients and extract and prepare all necessary information for the 3D database for said clients.

- Select and attribute costs to each selected item in the table.

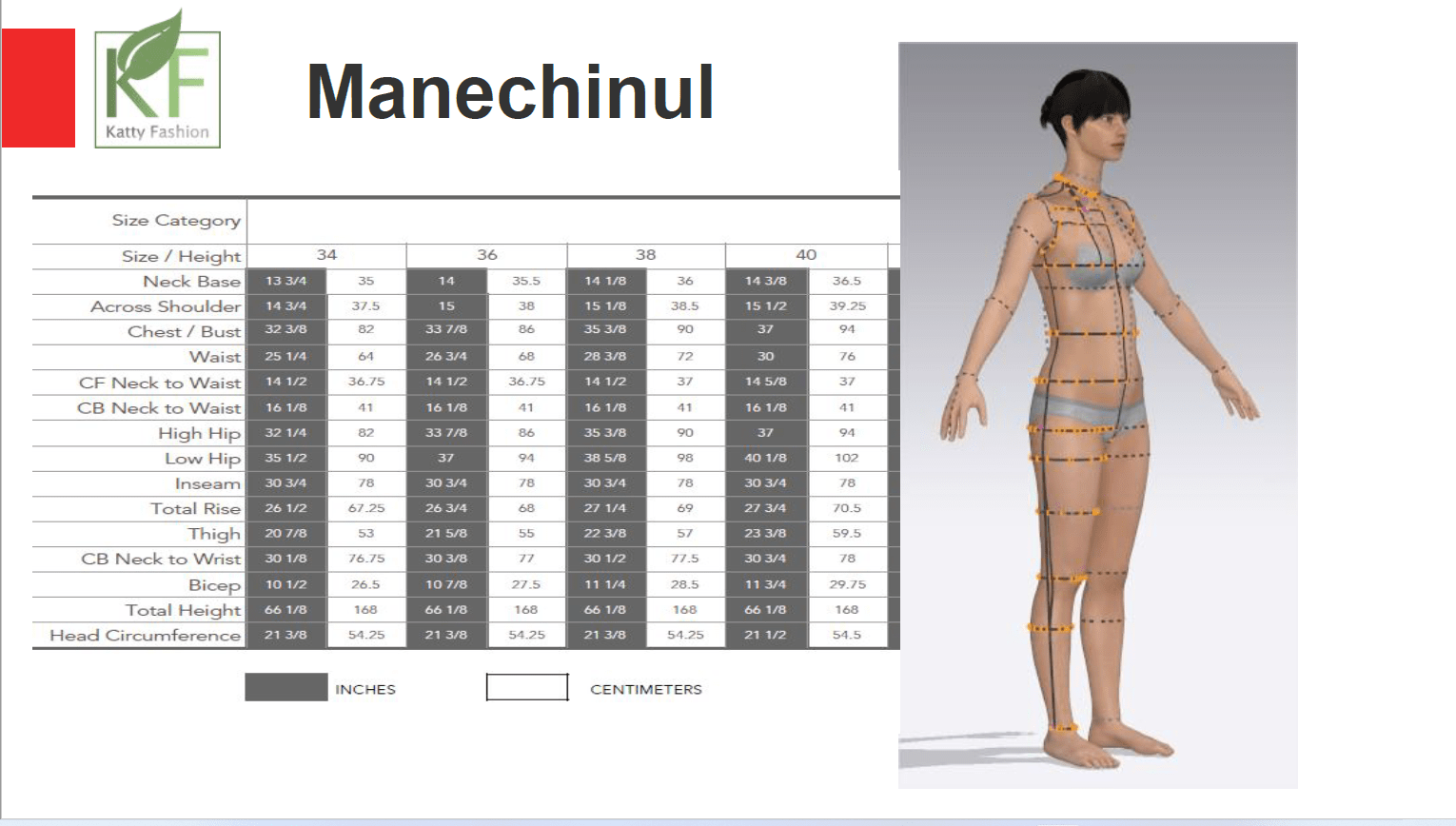

- Develop Body Shape Avatars (BSA) by:

- Developing BSAs for base sizes.

- Developing BSAs for the relevant sizes of our selected customers.

- Testing BSA performance.

- Build Pattern Blocks by:

- Developing and confirming relevant pattern blocks in a collaborative manner.

- Building 3D modelling capabilities within the KF team

- Developing Basic blocks 1 through 4.

- Identifying weaknesses or difficulties in the process/concept.

- Engaging in know-how exchange and performing cross-check validation.

- Building Digital Asset Database by:

- Integrating all activities in the Cloud/servers.

- Creating a template library.

- Uploading developed materials.

- Developing Homewear & Business Chic Wear Digital Components

- Developing Homewear & Business Chic Wear Digital Stiches

- Developing Homewear & Business Chic Wear Digital Materials

- Performing Database testing.

Stage 2: Solution validation (a sustainable alternative to the traditional waste-creator design process – adopting the novel technology of collaborative design and virtual prototyping (VP) – smart modelling) . with 4 KF’s relevant customers within 2 main product categories (home-wear and business chic women’s wear). If solution is validated, we aim it to become core KF service line in 2024. In order to conduct the solution validation we will ingage in the following series of activities:

- 3D Modelling Testing through:

- KF Client collaboration by engaging in buy-in activities.

- Collaboratively prototyping with KF clients in Homewear and Business Chic Wear

- Collecting performance metrics and analyzing the 3D performance.

- Implementing fixes and suggestions in order to improve the final product.

Stage 3: Developing a successful DIH business model around introducing Smart Modelling as an alternative to traditional wasteful design process in the fashion & textile industry in North East Romania region. In order to develop the business model we will conduct the following activities:

- Attend trainings

- Conduct service evaluations

- Leverage all support from the DIH World network to develop a successful DIH business model that will transform the region`s textile industry.

Stage 4: Dissemination of DIH World consortium and network objectives under use-cases from the Romanian textile industry

We will implement the requirements related to the visibility of the DIH World program, visual elements, distinct communication approach as its own etc. To increase the desired impact of dissemination and communication activities a system to measure the communication impact will be implemented. This will include various technical and marketing solutions (SEO, target groups identification, interlinking with other systems, etc.). The target groups of the dissemination and communication are divided into two categories, where appropriate communication channels and messages will be presented:

- Direct targets at national & EU level, with associated communication messages to it:

- TG1: Textile & fashion industry owners and employees, to which we address messages expressing the need for industry specialists and digital skills

- TG2: Representatives of SMEs, public sector and other institutions to which we present the program benefits and reason for which to engage in similar business development.

- Indirect targets at national & EU level, with associated communication messages to it:

- TG3: SMEs, associations, regional business innovation ecosystems which will receive general information regarding our activities

- TG4: The public at large which receives content related to sustainable business opportunities, digital skill requirements and more that are in line with our project.

For this we will select communication channels tailored to the target groups: • TG1, TG4: social media and online medium, with some local events. TG2, TG3: social media and the online medium, as they became crucial channels for information generation, dissemination, consumption, and professional interactivity during the 2020-2021 crises.

Impact of the experiment

The experiment not only will provide the SME with a digital maturity boost (by digitising traditional design processes, main creators of waste and manual interactions), but will be a best practice case to be used further in the region by the DIH to improve other textile SMEs digitalisation level. This will create an economic impact into the whole textile value chain (fashion producer, fashion designer and customer).

Furthermore, as previously stated the SME will obtain a better position on the market and become more competitive by increasing its efficiency and effectiveness in the manufacturing process. As a sizable investment the implementation of the 3D modelling will also increase the future opportunities of the SME in the 3D fashion modelling niche and be used as a stepping stone for future strategic activities like digital twinning and 3D virtual clothing, and even 3D custom clothes printing.

Fig. 3: Kick-off Meeting.