Experiments

Monitoring eco-friendly quality of the PET bottle manufacturing using advanced AI (AI4GreenPET)

Serbia, Nis

![]() Sibiu Smart Systems

Sibiu Smart Systems

Experiment objective

An AI-based software-hardware infrastructure for monitoring, analysing and controlling the eco-friendly quality of PET bottle manufacturing can provide numerous benefits for the production process. This infrastructure can use a variety of sensors and cameras to collect data on the production process, including the raw materials used, the manufacturing steps, and the final product. This data can then be analysed using machine learning algorithms to identify patterns and detect any potential quality issues.

One key feature of this infrastructure is the ability to perform real-time monitoring and analysis of the production process. This can enable the system to detect and respond to potential issues in a timely manner, before they lead to significant problems. For example, if the system detects that a batch of raw materials is not meeting the desired eco-friendly standards, it can automatically adjust the production process or stop the production until the issue is resolved.

In addition to detecting and responding to quality issues, this infrastructure can also be used to optimise the production process for improved efficiency and reduced waste. For example, the system can be used to identify bottlenecks in the production process and to adjust the manufacturing steps to improve throughput. This can lead to a more efficient production process and can help to reduce costs and improve the overall eco-friendly quality of the final product.

Initial product before high temperature and pressure.

Challenges

Challenge 1: The SME needs to install sensors in order to read the data as well as collect the data and provide it to the DIH.

Challenge 2: Analysing the data provided by the SME and understanding it by using data science and other tools.

Challenge 3: Using the data to achieve the objectives provided by the SME as well as the AI4GreenPET experiment.

Challenge 4: Integration of the AI-based system with existing manufacturing systems and processes. This requires careful planning and coordination to ensure that the new system can seamlessly interact with existing systems and processes without disrupting the production process.

Challenge 5: Developing the algorithms that will be used to analyse the data and identify patterns and issues requires significant expertise in machine learning and data analysis. This can be a challenging task, especially for organisations that do not have an in-house team with these skills.

Implementation of the Solution

The implementation of the solution is based on the data provided by the SME to the DIH. The sensing data from different sensors is collected at a temporal resolution of 1 seconds consisting of various electrical data as well as environmental data. Once a data cleaning pipeline is established, consisting of mainly getting rid of sensor values or invalid readings as well as resampling the data to a lower temporal resolution to be easier to test various AI algorithms.

The main purpose of the AI algorithms such as SVM’s, Markov predictors or other classifiers is to detect automatically which mode the equipment is currently working in as directed by the SME, with the main purpose of being able to know the working mode as well as detect variations which would cause the machine to work improperly. The fault detection will be on a continuous stream of data with the hopes of being able to predict future equipment failures or errors in the production which would cause environment waste or waste of product.

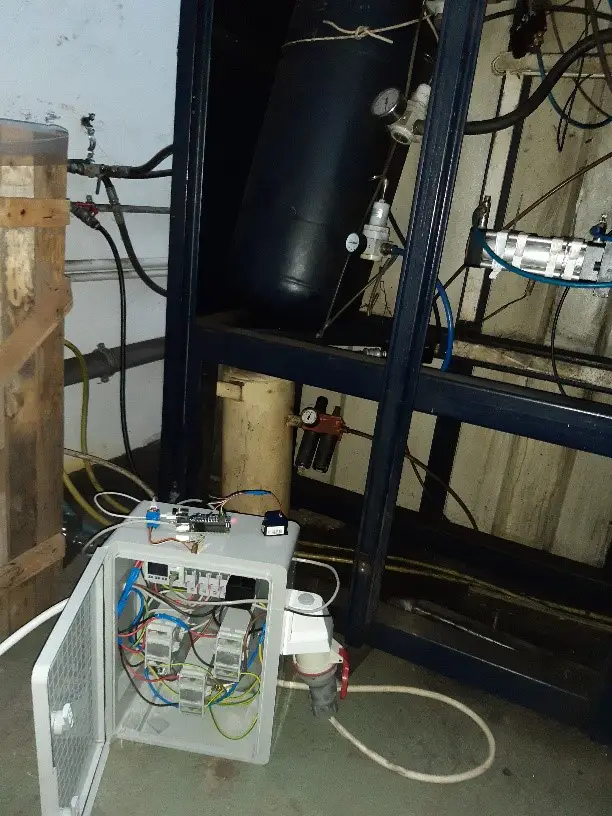

Power sensor box

Power sensor with environment equipment.

Sensors equipment beside machine for monitoring

Dissemination

Three channels are:

– Online Dissemination: The webpage in in progress. It will provide a first access point for interested parties.

– Social media: LinkedIn will be used for the dissemination of the results

– Non-Electronic Dissemination: Classical vehicles of knowledge transfer such as industry fairs, as well as articles in industry-relevant journals, and workshops focus on the dissemination of project results, mainly to experts and professionals.