Experiments

RainBOT

ITALY, Lombardy

![]() MADE – Competence Center i4.0

MADE – Competence Center i4.0

Experiment objective

RAINBot aims at introducing a collaborative robot within production line of solenoid and electric valves for the production of smart irrigation system. It will support the transition of an renovate business model within the post pandemic market. Indeed the general objectives of the projects aims at boosting SME.

- resilience, developing a lean and agile business model facing post pandemic global market dynamics

- competitiveness in global value chain, ensuring a fast answer to evolving customers demand leveraging quality, cost efficient, personalized products

- upskilling of workforce, allowing existing operators to enhance digitals skills in the post pandemic world

- enlarge international ecosystem, networking with DIH World community

Challenges

RAINBot will support RAIN to face the following challenges:

- Quality/Productivity: Increase quality of product ensuring lean and efficient manufacturing process;

- Competitiveness: Increase customer satisfactions while increasing market share in international market;

- Sustainability: decreasing time to defect detection;

- Human centricity: Improve quality of job and upskilling of existing workforce towards robotics technologies, shifting their working time to higher value activities enhancing human work.

Implementation Solution

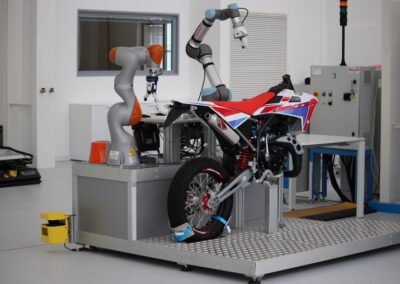

The experiment implementation is guided by Technical and horizontal activities. Rain will develop preliminary testing in a pre industrial scenario in the technological use case at MADE premises through an iterative approach. Finally the solution will be validated at industrial scale at Rain Spa premises.

Basing on Rain desired scenarios, Rain and MADE will identify RainBOT operational, usability and safety requirements and parameters in term of space, alternative layout, lead time (e,g, MTM, RTM), image acquisition speed, new AI set up to recognize different data patterns and to power machine learning. A specific focus is given to impact assessment on workers in term of safety (e.g. performance level rate), and impact on work stress related condition.

Requirements will be simulated at MADE premises. MADE will support Rain developing a strategic roadmap to adopt digital and automation technologies, including a focus on skills, to facilitate industrial uptake

Results of activities are implemented in real industrial scenario at Rain premises. Identified requirements will be transferred to existing cobot within the production solenoid assembly line. Identified skills gap will be addressed through dedicated training course in cooperation with DIH World community.

The work package will implement the dissemination plan, leveraging DIH World community. Partners’ Social media will be exploited to disseminate project activities and results; informative webinars are organized in cooperation with relevant stakeholder (e.g. Enterprise Europe Network, Business Association, Standardization Body). Success stories will be promoted through online video, in addition to project Trial Handbook contribution. Partners will actively participate in DIH World community events (e.g. DIH World Days). Furthermore commercial exploitation and RainBOT business model is defined.

Management will grant deliver of results on time, budget, quality in coherence with DIHWorld reporting rules. It will included a continuous risk assessment and release periodic sots statement ensuring cost and technical activities progress. Kick off and monitoring meeting will ensure alignment with DIHWorld management team.

Results Obtained

Rain SpA is able to experiment for the first time a digital open innovation methodology through the cooperation with Digital Innovation Hub (MADE) in a test before invest scenario, while exploiting DIH World network and services. The project, starts from TRL7 as the cobot is integrated, qualified and operational within a limited set of tasks at Rain SpA headquarters. In addition the AI system is trained to recognize a limited subset of defects. RainBOT is expected to reach TRL 8, through the qualification of optimized requirements allowing and industrial uptake at Rain SpA premises.

Expected results are

- Increase of cobot productivity, improving mechanical and performance requirements both of collaborative robots and AI vision system

- Develop of new lean business model thus increasing company attractiveness through a lean design optimization of solenoid production lines

- Improved job quality through upskilling system

- Realization of 3 test before invest experiment

Impact of the experiment

RainBOT will disrupt Rain SpA business model in the post pandemic uptaking human machine interaction technologies, leveraging

RESILIENCE. Cobots enables humans and machines to work simultaneously in the components collection operation, reducing contact between workers thus maintaining safe social distancing standards.

HUMAN CENTRICITY. Eliminating recurring monotonous work tasks, operators have more time to focus on high added value activity. Furthermore it will allow to upskill existing workforce, educating people to interact and use robotic technologies.

SUSTAINABILITY. Robotic system will enhance zero defect production system, reducing defected valves and components at the end of production system. It will potentially eliminate process waste ensuring quality of products enabling a sustainable business model.

CROSS SECTORAL. RainBOT can be scaled to impact on products with different market application (e.g. civil building, home, sports) manufactured at Rain SpA factory lines.

RainBOT will generate impact on

CROSS BORDER COOPERATION. Access DIH World community will open up cooperation with DIHs located in the most competitive EU Regions. It is a unique opportunity for MADE to expand the network of Learning Factory in different EU countries, enhancing exchange best practice to improve existing services (e.g. Digital maturity assessment);

INDUSTRIAL R&I PROJECT. Develop new interregional industrial R&I projects in cooperation with DIH World ecosystem (DIH, SME, University, Business association) in the framework of 2021-2027 EU R&I funding (e.g. Horizon Europe Cluster 4, Digital Europe, Interreg);

BUSINESS MODEL. Improve its business model focusing on financial sustainability mechanisms, management of cross border DIHs ecosystem, measurement of intangible impact of DIHs activities on client. In particular it will exploit the concept of Lean Robotics

Dissemination

Rain and MADE will actively participant in DIH community days to promote best practice exchange and cross fertilization. Partners will actively disseminate RainBOT and DIH World outcomes within their stakeholder network leveraging social media (e.g. Linkedin, Twitter), online communication (e.g. webinar), Lombardy region Open Innovation platform and institutional website.

Dissemination will target SMEs in the field automation solution for agriculture and water management, willing to deploy robotics system in their manufacturing lines, Academia and Business Association. Synergies with Enterprise Europe Network and Vanguard Initiative is fostered.

Following the link to the project page on the made website: