Experiments

Smart system development for nanobubble technology to improve the food production ecosystem (SMARTNANO4FOOD)

Slovenia

![]() DIH Healthday.si

DIH Healthday.si

Experiment objective

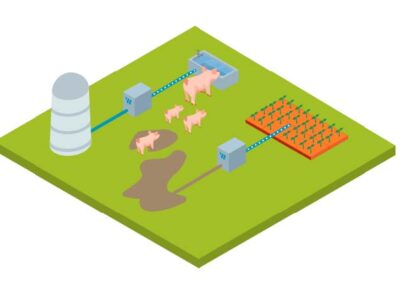

The experiment’s main objective is to improve the current state-of-the-art with digitizing the control system of Waboost Nanobubble technology using the advanced technologies of IoT, cloud technologies and data analytics connected with the already integrated sensor systems in Waboost Nanobubble technology.

The project’s outcome is an automated and online controlled, regulated, and measured Nanobubble technology suitable for different irrigation systems in food process sector. It will be achieved by the development of a smart system for Nanobubble technology devices, shifting from current manual state to automated digital system.

After the experiment, the data from the IoT system will be further analysed in the cloud to make suggestions on machine operating improvement in certain use cases. The digitization of the Waboost nanobubble systems for irrigation processes will reduce the workload of the end-user in food process industry and at the same time make the irrigation more efficient.

The outcomes of the experiment will raise the awareness of the benefits of the smart system controlled Nanobubble technology and increase Waboost (digital) competitiveness over existing providers and old techniques across EU and the agriculture stakeholders.

Challenges

Challenge 1:

The existing aeration technologies have difficulties achieving the requirements for minimal needed oxygen levels in irrigation water for the diverse types of plants. The oxygen level decreases according to the length of the piping system and the time it travels from the aerator to the final crop. Therefore the plant’s roots and plants itself have the lack of oxygen which has an impact on production yield, product quality and bigger demand on pesticides.

Pilot Experiment Template

Waboost has identified the problem and developed an innovative hyper-aeration nanobubble system with integrated in-site oxygen generator to provide highly efficient injection of long-living oxygen into the water.

Challenge 2:

Currently Waboost nanobubble machines (systems) work based on pre-defined timers and manual control mode. The sensor system is connected and collects basic parameters in the cloud. It also supports a fraction of online control like turning it on or off remotely. However, the current condition does not yet allow to precisely control all parameters of machine producing the nanobubbles, enabling the control over the whole system and collecting all data in the cloud system.

From the previous use cases and testing with the early adopters Waboost identified the need for automated control system and higher digitalisation of the Nanobubble technology.

It is expected that the results of this Project (the new IoT based solution) will help to adjust levels of nanobubbles and improve machine operation to produce best results for the target clients in food process sector and make the water hyper-aeration system process more efficient. The end-users will no longer have to experiment how long they should run the machine since it will be able to operate completely autonomously based on user preferences. The data collected in the cloud will enable future analysis, improving the efficiency of the irrigation system on diverse applications.

Implementation Solution

In the experiment, Waboost will improve the current state-of-the-art with digitizing the control system of its Nanobubble technology using the advanced technologies of IoT, cloud technologies and data analytics connected with the already integrated sensor systems.

To achieve main and other Experiment objectives following steps – WP will be done:

Strategy / Action plan – On the basis of current digital state of the Waboost products/machines, on the basis of professional and market research and on the basis of predefined Project milestones a Strategy/Action plan, including structure – modules was prepared. Action plan contains modules:

1. Device controller electronics IoT prototype validation and production test

2. Sensor unit electronics IoT – prototype validation and production test

3. Device smart power box (IoT ready) – prototype validation and production test

4. Cloud platform for IoT (Blynk) – service validation and test

5. Mobile remote management application validation and field demonstration

6. Time series big-data storage and server prototype and validation

7. Big data visualisation & analytics dashboard tool prototype and validation

8. Control algorithms – Sensor and parameters aware– modelling, prototype validation and test

9. Cloud to Big-data storage data transfer and validation algorithm– modelling, prototype

Those modules will be developed in further steps. WP2 (Smart system development) and fine-tuned in WP3 (Laboratory validation) and WP4 (Field validation);

- Smart system development – Waboost digital solution for control operation and regulation of the nanobubble devices will be upgraded from TRL 4 to TRL 6 using state of the art technologies;

- Laboratory validation – Developed Smart digital system will be tested in Waboost laboratory in Ljubljana, Slovenia;

- Field validation – Laboratory tested and validated Smart digital system will be finally tested on real case. It is planned that the part of the test will be conducted in one of the Greenhouses in Slovenia and the second part in the greenhouse in Italy.