Experiments

Structurescope EG + AI

Ukraine, Kyiv

![]() NOSC-UA DIH

NOSC-UA DIH

Experiment objective

The concept of the Structurescope EG + AI experiment lies in combining the Structurescope EG technology with artificial intelligence (AI). The introduction of AI will reduce the duration of the analysis, which will increase productivity and, consequently, the efficiency of SMEs and their customers. Our team has developed and constructed the Structurescope EG for industrial production application, which can replace 80 % of metallurgical testing (MT), reduce the time for inspection of compliance to the structural requirements by ten times and fully automate this process.

The Structurescope EG technology is based on a multi-frequency eddy current (MFEC) NDT cyber-physical system which applications are governed by the standards of ISO 10893, ISO 15549, ISO 12718, ISO 15548 series. Due to the use of multi-frequency digital signal processing (DSP), possibilities of the Structurescope EG compete with MT systems. MT has the highly regulated standards, is a labour-intensive “manual” technological operation, and involves production of the special samples on the special equipment, followed by their testing on the other specific equipment. The specific equipment for MT has a significant cost (a fully equipped laboratory costs from five million dollars) and requires the highly qualified personnel (at the level of scientists). That is why only global manufacturers or specialized companies can afford themselves organization of MT laboratories, which ultimately adds financial and time logistics losses for MT consumers. At the same time, almost any critical components (СС) production requires conducting a whole series of MT tests.

Based on the needs of identifying the material properties, such as fatigue, type of structure, hardness, toughness, or others, the Structurescope EG algorithms are set for DSP and tested material scanning. As a result, high-precision values of the higher harmonics amplitude and phase are obtained, which are interpreted according to a given algorithm for the signal synthesis and scanning of the material, its type and geometric shape. It is the AI that is tasked with the rapid, accurate interpretation of the APAC obtained during the inspection process, i.e. AI becomes a key element of the technology in terms of its usability.

The experiment overall objective is to reduce the response signal amplitude-phase characteristics (APAC) interpretation time from 45 to 5 minutes by combining the Structurescope EG with AI technologies. Such reduction in the interpretation time becomes possible due to replacement of the human interpretation of APAC with artificial intelligence, which will significantly improve the level of its digitization, will turn long, complex processes of APAC interpretation into the data for decision-making, and accordingly, create conditions for full successful automation at our clients’ enterprises. The duration of such process within 5 minutes translates it into reduction of the CC material quality control time for our consumers from at least 3 days to the same 5 minutes.

In the course of the experiment, we will evaluate the effectiveness of the specified methods application according to the criteria of suitability for the formation of the APAC knowledge base in the form of analogues to the results of the MT different types, and apart from this, defining and forecasting APAC varieties.

The experiment results in the form of the AI implemented into the interpreting the APAC measurement results operations and image reconstruction will be used by us to fully automate the material structure determination technology and bring it to the level of cognitive autonomous systems, with the future transition to the automated design of scanner sensors and creation of digital twins of the structure of various materials and subjects and their large databases.

Samples of steel type 41Cr to determine the correlation between APAC and impact energy

Challenges

The Structurescope EG technology for determining the structure of materials is based on a patented method of determining the structure of the electromagnetic field emitted by the material due to its excitation. However, during the excitation of a material, harmful disturbances occur that affect the values of harmonics amplitude and phase. First of all, they are influenced by the temperature of the amplifiers semiconductors electronic components, heating of samples due to the eddy currents, establishment of the temperature equilibrium in the system device – sensor – material – ambient air. In addition, APAC is affected by the well-known in eddy current methods lift-off and edge effects due to the geometry of the control object.

In laboratory conditions, a highly qualified specialist can undertake certain measures to take into account the mentioned harmful effects when interpreting APAC, and it is these measures that require a lot of time and define limitations of full automation and industrial application of the Structurescope EG technology.

The war of Russia against Ukraine has become another serious challenge. All Ukrainian companies, SME’s potential clients, have been attacked by Russian troops to one degree or another, as they produce dual-use products, and cooperation with them is either impossible or dangerous.

Implementation of the Solution

Establishing correlation of the measured APAC with certain mechanical properties by conducting APAC measurements for the samples with determined mechanical properties. The measurements data will be uploaded on cloud services, and possible influencing factors determined. Since APAC contains information on the amplitudes and phases of five harmonics, as well as taking into account other influencing factors, multidimensional sets of statistical research will be applied.

Independent testing is planned to be performed on the site of a real industrial enterprise with the participation of DIH, which specializes in the implementation of AI. Testing of the Structurescope EG+AI will be carried out at the site of a selected industrial enterprise in Germany. Management of testing operations, elimination of the identified deficiencies, will be carried out remotely from Ukraine: in the Structurescope EG, as a cyber-physical system, such technologies are implemented The system management software will implement automated measurement and statistical processing of the duration of APAC interpretation operations, which will be presented to an independent examiner.

APAC measurement

Results obtained

|

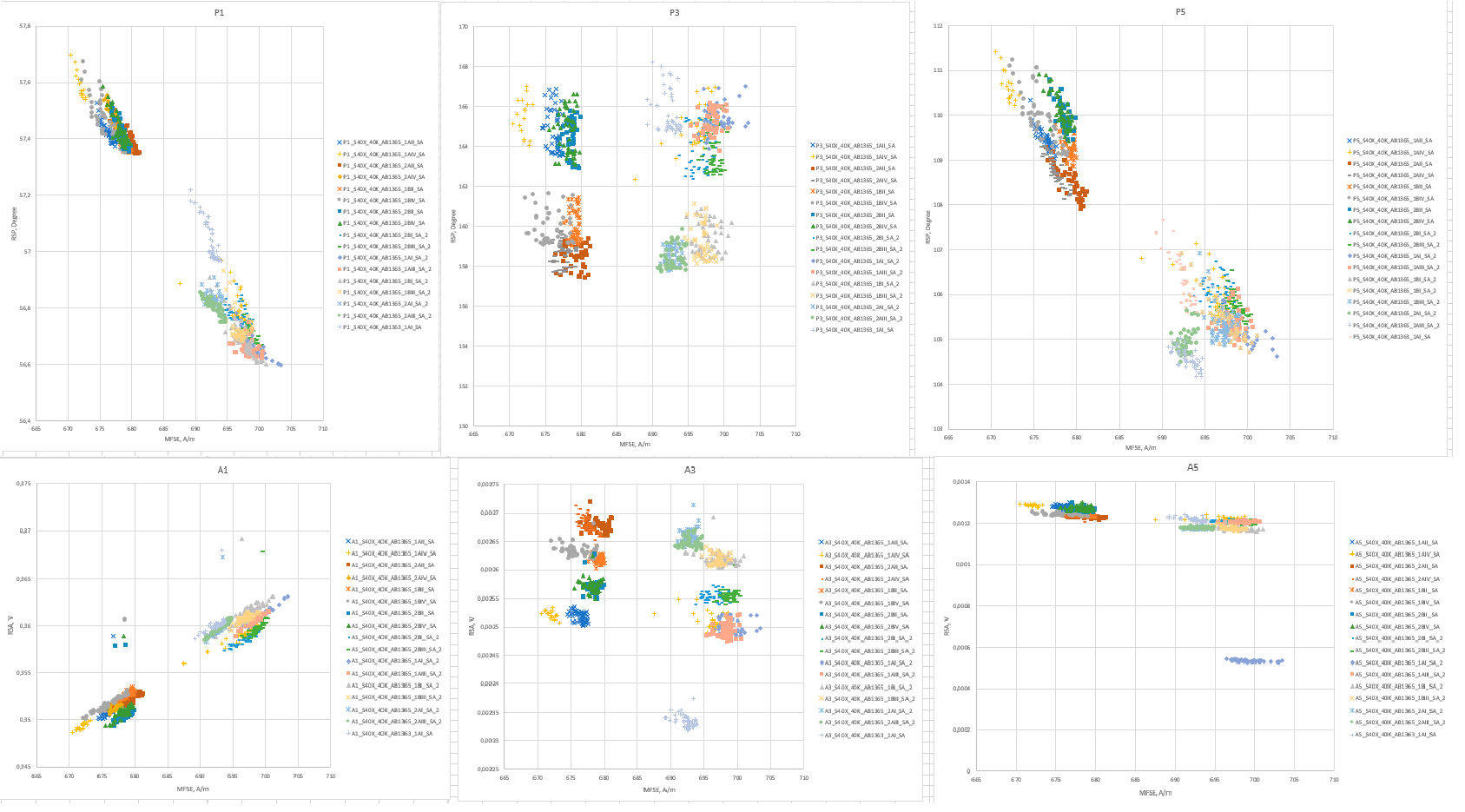

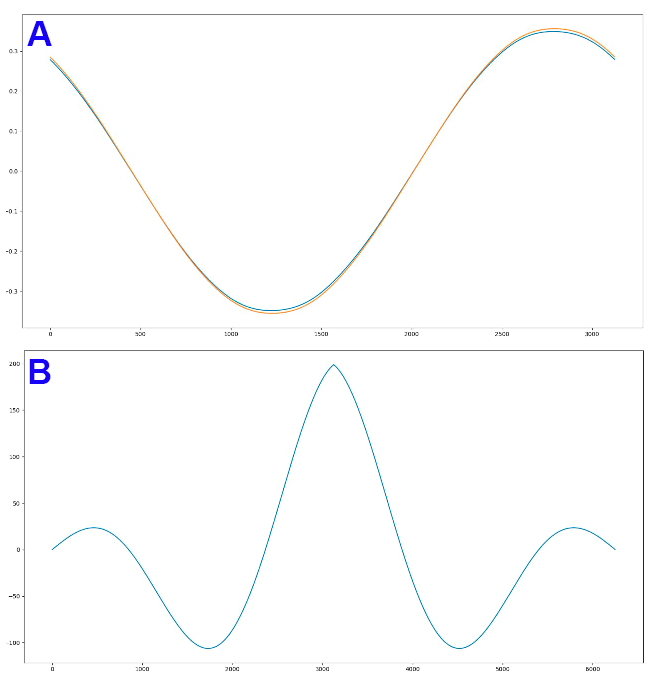

In the course of the experiment the samples with established properties were selected: Six samples of the steel 41Cr type, subjected to Impact toughness test according to the standard ISO 148-1, with known values of impact energy, Fig. 1. Measurements of АРАС conducted: Fig. 2, Fig. 3. Correlation is being determined: data for processing received, calculations are in process. Fig. 4 shows an example of determination of the correlating and the correlation value for two samples. Ahead of schedule there have been started the works on developing a new Structurescope EG+AI interface, which implied the changes in the system electronics Fig. 5. Due to constant shortage in electricity supplies in Kyiv (Kyiv has suffered a blackout with other regions of Ukraine due to Russian military aggression on the Ukrainian infrastructure) we had to transfer works to one of our team member’s home. Independent testing of the Structurescope EG+AI at the real production sites is an important part of our experiment. Direct access to such manufactures is complicated due to the fact that Aleistyn is a startup yet unknown among the manufacturers’ community of Europe. European DIHs, and German DIH in particular, who are located in Bavaria, have competences in AI, and have access to potential clients-consumers, can help our SME to reach this aim. Moreover, importance of the DIH partner in this aspect and influence of SSEGAI clients’ feedback are defined in THB (p.1.6 and p 4.2.3). It is foreseen that inquiry to several European DIHs with the proposition to involve potential clients-consumers of the Structurescope EG+AI will allow for a high effectiveness of the experiment works implementation, as well as for assured confirmation of its results, including its tasks defined in the Dissemination Plan. The listed herebelow are DIHs proposed for cooperation with the purpose to organize the Structurescope EG+AI independent testing as described above: Center Digitization Bavaria, ZG.BCenter Digitization Bavaria (CDB) develops competences in such potentially promising for us sectors as Mobility and Material & Production, demonstrates its close connections with production companies of these spheres according to their site information (cluster Mobility indicates 700 companies), though no particular names are given on the site. In the sector Mobility CDB focuses on the following directions: напрямках Electromobility, Electrics and electronics, Drivetrain concepts, Interior space and comfort, Intelligent Mobility. We can offer values in the cluster Drivetrain concepts, control of the structure of materials from which critical components of transmission are produced, which, in its turn, will drastically change the technology of their production. In the sector of Material & Production CDB specializes in the following spheres: New Material, Network Textile, Network of Innovative Solid Construction, Additive Manufacturing, Digital Production & Engineering, Mechatronics & Automation, AI Production Network. We can offers values in the cluster Digital Production & Engineering, direction Sensor technology in production as the Structurescope EG+AI is a sensor system in the digital production. The main concept of materials production is establishing precise and optimized properties of materials. Our system can become an instrument for realization of this concept in industrial scales. In the cluster AI Production Network we can offer a role of the independent appraisal of the Structurescope EG+AI effectiveness in terms of correspondence to TRL6 level. Munich Innovation Hub for Applied AIMunich Innovation Hub for Applied AI (MIHAAI) develops competences in the sphere of AI, one of its services is Assisted test environments, which implies Concept validation & testing. Thus, CDB is considered as a counterpart for inviting its partners or companies from the list herebelow, while MIHAAI is considered as a counterpart for independent confirmation of our technology readiness to correspond to the TRL6 level. Target companies of Bavaria region

Herebelow are given the names of companies with the reference to their sites, which operate in the sphere of machine engineering, and in the future can be interested in installation of the Structurescope EG at their production sites. At the current stage they can provide their production sites for the Structurescope EG testing:

|

[1] Heat affected zone (HAZ), about: https://www.twi-global.com/technical-knowledge/faqs/what-is-the-heat-affected-zone

An example of measured APAC of different samples of 1, 3, 5 harmonics

Impact of the experiment

In the course of the experiment implementation the NOSC-UA DIH is developing digital innovation services for scientists, business sector and public authorities using cloud technologies and such advanced technologies as AI, Big data and data sharing, Digital twins, IoT, AI, Blockchain and Cybersecurity. The experiment will impact the following spheres of NOSC-UA DIH activities: cooperation between researchers and innovation companies (in particular SMEs) based on digital technologies; new products and services using R&D, innovative digital technologies; integration of Ukrainian SMEs and researchers in the European Research Area and the EU Digital Single Market.

Correlation functions of 2 samples (A) and their correlation (B)

Dissemination

According to the wp the sendout of the experiment first newsletter for the period October-November was made to the following target audience:

ACEA, BDI, CBI, CEFIC, EUROMETAUX, EWEA, EUROPIAN ALUMINIUM, Kyiv Chamber of Commerce and Industry, MAKE UK, ME GESAMTMETALL, PWEA, UKRMETPROM, I4MS, EOSC.

The newsletter was also placed on the experiment pages:

https://www.facebook.com/profile.php?id=100088164824388

Works on creating a new interface